LuxaLight LED Engine UV-A 405nm Protected (24 Volt, 108 LEDs, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 23.13 W/sqm |

| 10cm | 9.36 W/sqm |

| 15cm | 4.67 W/sqm |

| 20cm | 2.82 W/sqm |

| 25cm | 1.86 W/sqm |

| 30cm | 1.42 W/sqm |

| 24V | |

|---|---|

| 5cm | 412.1 W/sqm |

| 10cm | 172.8 W/sqm |

| 15cm | 87.6 W/sqm |

| 20cm | 53.75 W/sqm |

| 25cm | 35.37 W/sqm |

| 30cm | 27.05 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

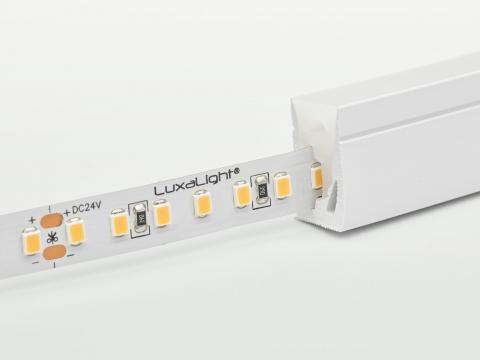

The LuxaLight LED Engine UV-A 405 nm (Protected, 24 V) is a semi-finished aluminum PCB module, developed for engineers and OEMs seeking a violet/UV-A light source for integration into custom fixtures, optical systems, or R&D setups. It delivers only the light-emitting core, offering maximum flexibility in thermal management, optics, and housing design.

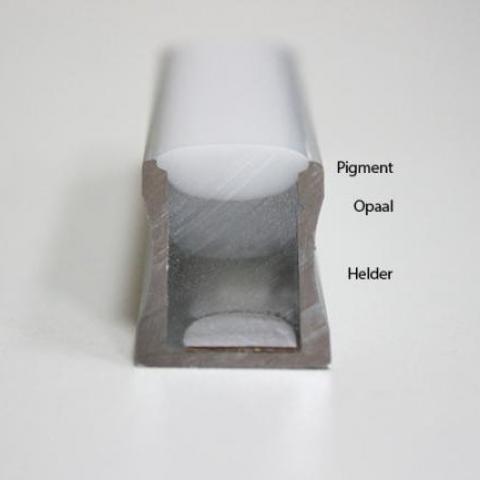

With 108 × 2835 SMD LEDs, an industrial silicone coating providing IP64 protection, and an integrated NTC temperature sensor, the module ensures reliable performance in demanding environments. Combined with the MaNima Pollux Industrial System, the engine becomes a complete, high-efficiency UV solution, unlocking improved efficiency through pulsing and advanced thermal control.

Key Specifications

| Property | Value / Description |

|---|---|

| Type | LED Engine – semi-finished PCB module |

| LEDs | 108 × 2835 SMD LEDs |

| PCB base | Aluminum |

| PCB protection | Industrial silicone coating (provides IP64 rating) |

| Dimensions | 200 × 20 × 2 mm (modular design) |

| Supply | 24 V DC / ~30 W |

| Wavelength | 405 nm (UV-A), peak ~404 nm |

| Irradiance (5 cm) | ~412 W/m² total radiant power @ 24 V |

| Beam angle | 120° |

| Thermal monitoring | Integrated NTC sensor (5 kΩ, β = 3950) |

Applications

- Resin & 3D printing photopolymerization – optimized for curing resins sensitive to 405 nm, widely used in additive manufacturing.

- Coating & adhesive curing – suitable for materials designed for longer-wavelength UV curing, reducing material stress.

- Fluorescence excitation – excites specific dyes and markers in biology, chemistry, and quality control applications.

- Antimicrobial surface treatment – 405 nm UV-A reduces bacterial load, useful for hygienic and biomedical applications.

- Machine vision with violet contrast – enhances visibility of inks, coatings, and security features not seen under white light.

- Research & laboratory use – versatile UV-A source for experiments where controlled, less aggressive UV is required.

Also applicable in R&D and specialized lighting setups.

Benefits for Engineers

- Semi-finished module – ideal for OEM and R&D integration

- Perfect Pollux companion – transforms into a complete UV-A system with MaNima Pollux

- Improved efficiency with Pollux – pulsing and thermal control maximize performance

- Design freedom – integrate into your own housing, optics, and thermal setup

- High UV intensity – ~412 W/m² at 5 cm supports demanding curing and inspection tasks

- Modular scalability – multiple engines can be combined as required

- Thermal safety – NTC ensures stable operation and long service life

- Industrial durability – IP64 protection via silicone coating

Integration with MaNima Pollux Industrial System

- Real-time NTC temperature monitoring

- Pulse/strobe modes for higher peak intensities and improved efficiency

- Prevents overheating while maximizing UV performance

- Provides data to PLC/SCADA automation systems

- Open UDP-based API for advanced system integration and customization