LuxaLight Industrial LED Fixture Transparent IP68 UV-A 405nm 24.2x16mm (24 Volt, 2835, IP68)

Technical specifications

| 24V | |

|---|---|

| 5cm | 26.3011 W/sqm |

| 10cm | 9.24065 W/sqm |

| 15cm | 4.60121 W/sqm |

| 20cm | 2.74051 W/sqm |

| 25cm | 1.76836 W/sqm |

| 30cm | 1.2926 W/sqm |

| 24V | |

|---|---|

| 5cm | 443.4 W/sqm |

| 10cm | 165.1 W/sqm |

| 15cm | 82.15 W/sqm |

| 20cm | 49.01 W/sqm |

| 25cm | 32.08 W/sqm |

| 30cm | 23.41 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

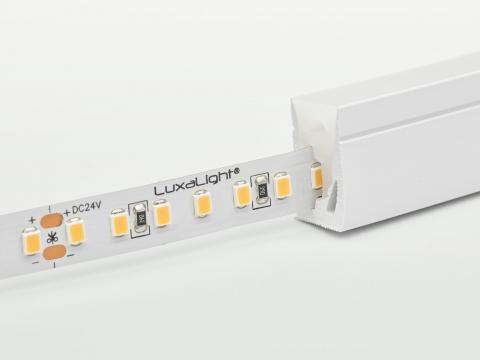

The LuxaLight Industrial LED Fixture Transparent IP68 UV-A 405 nm (24.2 × 16 mm, 2835 LEDs) is a fully encapsulated, moulded LED solution designed to withstand the harshest conditions. With a polyurethane-moulded housing (IP68), high-intensity UV-A output, and seamless integration with the MaNima Pollux Industrial System, this fixture offers durability, uniform lighting performance, and reliability in outdoor, marine, industrial, and submerged environments.

Key Specifications

| Property | Value / Description |

|---|---|

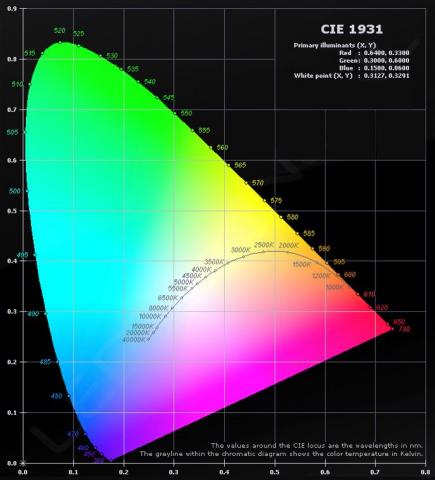

| Wavelength | 405 nm UV-A (measured peak ~405 nm) |

| Optical Output | ~443 W/m² @ 5 cm; ~165 W/m² @ 10 cm; ~82 W/m² @ 15 cm |

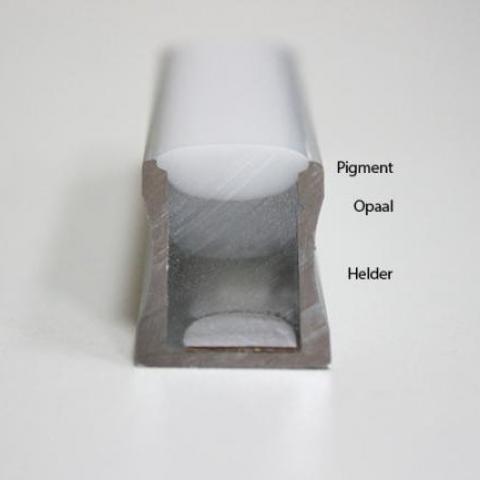

| Cover | Fully moulded transparent polyurethane encapsulation |

| LED Type / Protection | 2835 LEDs; IP68 encapsulated (dust- and waterproof) |

| Beam Angle | 120° |

| Voltage / Power | 24 V DC, ~30 W per fixture |

| Thermal Monitoring | Integrated NTC sensor, controllable via MaNima Pollux |

| Design | Modular & scalable, 220–3000 mm |

| Dimensions | 24.2 × 16 mm profile |

| Operating Environment | Outdoor, marine, industrial, and submerged use (–5…+60 °C) |

IP68 Moulded Design – Fully Encapsulated Housing

This fixture is completely encapsulated in transparent polyurethane, offering:

- IP68 waterproofing – fully protected for submerged or exposed environments

- High mechanical resilience – robust against shock, vibration, and impact (IK10 equivalent)

- Stable optical output – consistent UV spread through the encapsulated cover

- Maintenance-free design – seamless housing resistant to dust, dirt, and corrosion

- Extended durability – protects LEDs and electronics from moisture, chemicals, and environmental stress

- Engineered for extremes – reliable in marine, outdoor, and harsh industrial settings

Applications

- UV-A Curing of Adhesives & Coatings – in outdoor, humid, or submerged conditions where reliability is critical

- 3D Printing & Dental Applications – deep penetration curing in environments with high humidity or dust

- Food & Medical Disinfection (violet light) – antimicrobial effect on surfaces in wet or exposed areas

- Industrial & Outdoor Surface Inspection – robust performance in dusty, wet, or chemically exposed production sites

- Marine & Offshore Lighting – durable UV-A source for underwater or saltwater applications

- Fluorescence Excitation – reliable detection of dyes and markers in challenging environments

Also applicable in optical bonding and advanced R&D environments.

Benefits for Engineers

- IP68 polyurethane encapsulation – waterproof, dustproof, and maintenance-free

- Shock & vibration resistant – durable housing protects internal components

- Consistent lighting – uniform UV output through encapsulation

- Extended operational life – resistant to environmental stressors like corrosion and moisture

- Automation-ready – seamless compatibility with Pollux, PLC, and SCADA systems

Integration with MaNima Pollux Industrial System

- Real-time NTC temperature monitoring

- Pulsing/strobing for optimized peak output

- Thermal overload protection for continuous operation

- PLC/SCADA system compatibility

- Open API (UDP-based) for advanced automation