Machine Vision

LED Interfaces for Machine Vision Applications by MaNima Technologies

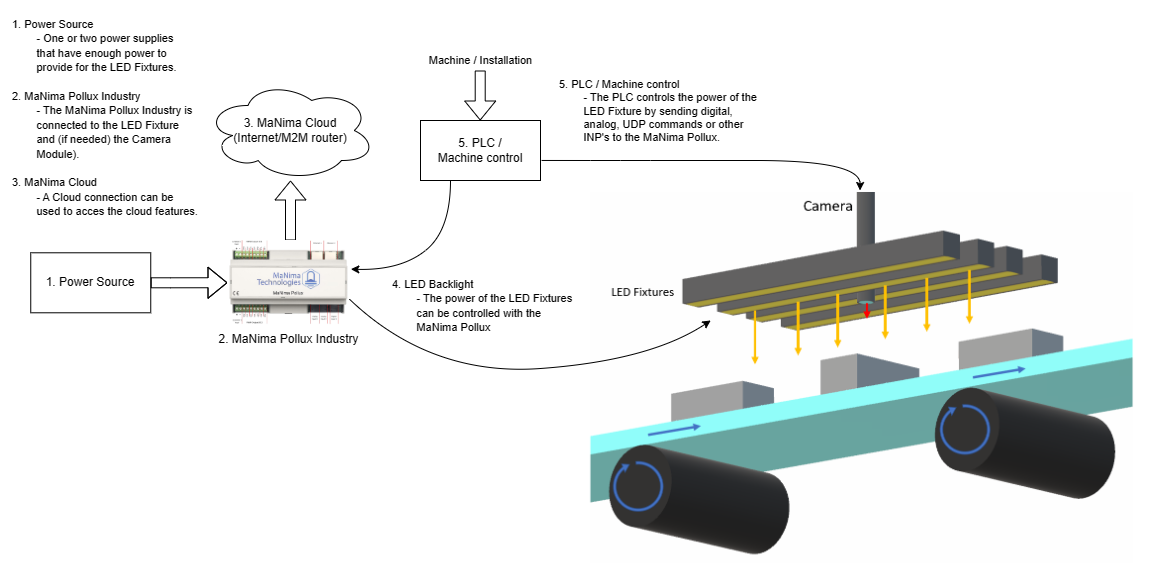

MaNima Technologies provides advanced LED interfaces designed for a wide range of machine vision applications within the robotics and automation industries. With the support of our engineering team, we can seamlessly integrate both the hardware and software into new or existing systems and machines.

Configuration and Control:

Key parameters such as output intensity, exposure time, and triggers are easily configurable through tools like the MaNima Configurator, MaNima Cloud, and UDP commands, allowing for precise control of the LED systems.

Typical Applications for LuxaLight LED Machine Vision Systems Include:

- Material surface defect detection

- Fluid leakage control

- (Hyper)spectral Imaging

- Hydrocarbon detection

- Clearcoat inspection on PCBs

- Real-time line scan cameras

- Barcode scanning

- Pharmaceutical industry applications

- Food inspection (agro-food)

- Detection of germs and germicidal substances

- Agro-Robotics

The MaNima Pollux Industry, designed by MaNima, offers a wide range of inputs and outputs, including digital contacts, Ethernet, and various Industrial Network Protocols, ensuring compatibility with a broad spectrum of industrial systems.

Pulse Mode for Enhanced Control:

The MaNima Pollux Industry also features a pulse mode, enabling the use of 8 speed-optimized digital inputs. These inputs control the PWM outputs, which can pulse at rates between 2µs and 1000ms. Pulse mode is particularly useful for synchronizing strobe times with the exposure times of machine vision cameras, enhancing the performance and accuracy of image capture in dynamic environments.

For more information about the MaNima System click here.

Properties LuxaLight industrial LED engines

The technical properties of a LED engine are determined on the basis of the application:

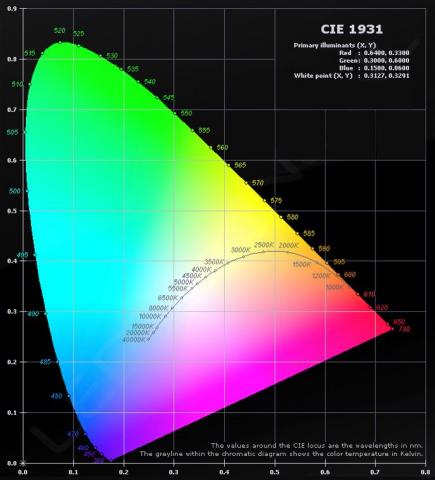

- Wavelength

- Heat management

- Lumen/ radiance per m² (lux/ radiance)

- Opening angle

- Distance from LED engine to object/ surface

- Dimensions object/ surface (maximum)

- (Maximum) mechanical dimensions

- Impact resistance (IK value)

- Waterproofness (IP value)

LuxaLight has the technical knowledge in the field of software and hardware engineering that makes it possible to develop a custom-made LED solution when a standard product is not sufficient.

Wavelengths in our product portfolio:

- 365nm and 395nm (UV-A)

- 405nm (UV-A)

- 450nm (Blue)

- 525nm (Green)

- 640nm (Red)

- 660nm (Deep Red)

- 735nm (Far Red)

- 860nm and 960nm (Infrared)

- 4200K and 4800K (Neutral White)

- 5700K (White)

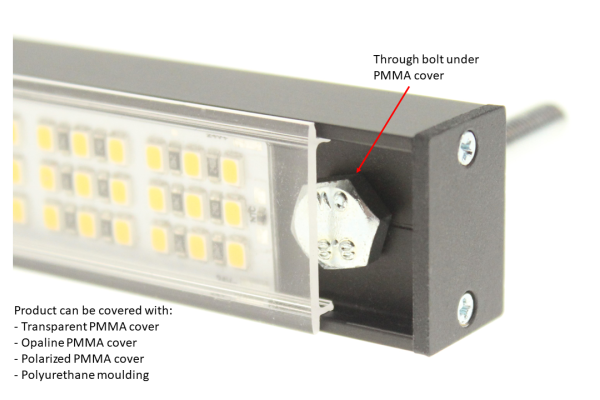

Enclosures

A LED engine often has to meet certain mechanical requirements. By selecting the right mechanical requirements, a suitable housing can be selected. Mechanical requirements are often taken into account such as:

Modular and custom-made LED solutions

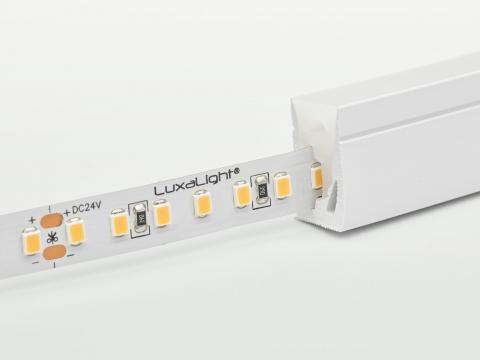

For LED solutions in the machine vision, we have industrial LED fixtures in the standard product portfolio.

which fit seamlessly with a wide range of machine vision solutions and offer the following benefits:

- Variable dimensions possible

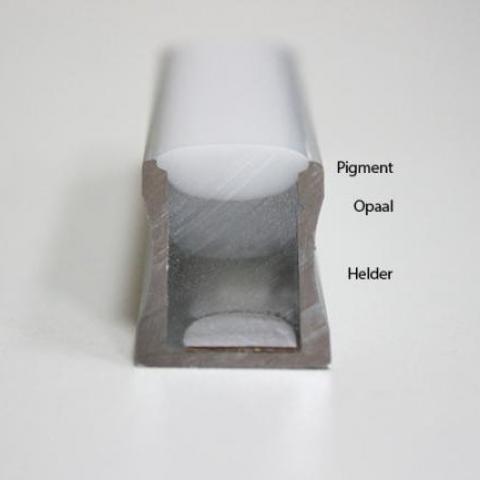

- Homogeneous light image by means of lens hood/ LED moulding

- LED moulding compatible

- Various opening angles possible due to optical lenses

- Various mounting options

- Possibility of multiple wavelengths in one fixture

- Economically beneficial due to modular construction

If the standard products do not meet the technical specifications, a custom-made solution is of course also possible.

Casting LED engines

In order to meet the technical requirements of the LED application, sometimes a choice has to be made for casting the housing. The composition of the casting resin is determined by the application. Click here for more information about LED moulding.

For appropriate advice, it is always possible to contact us without any obligation.