LED Monitoring

Monitoring of LED installations

To ensure the longevity of an LED installation, it is essential to monitor it in real-time across various parameters. The MaNima Pollux is used to perform this real-time monitoring of the LED installation. Monitoring the LED installation is performed by the MaNima Pollux.

Electronic monitoring

Electronic monitoring of an LED installation includes the measurement of key parameters such as current, voltage, power, and PWM signals. The MaNima Pollux tracks both input and output parameters in real-time. If the MaNima Pollux detects any deviations from preset values at the primary and/or secondary input and output, it automatically switches to a predefined mode (action) to maintain system integrity.

Current and short circuit protection

Real-time monitoring of electrical properties allows the MaNima Pollux to measure current fluctuations, detecting any deviations or irregularities promptly. If necessary, the Pollux can intervene to prevent the installation from being exposed to excessive peak currents or short circuits. This protective feature helps avoid collateral damage during faults or deviations, which can result from issues like maintenance, vandalism, or environmental damage.

Temperature monitoring

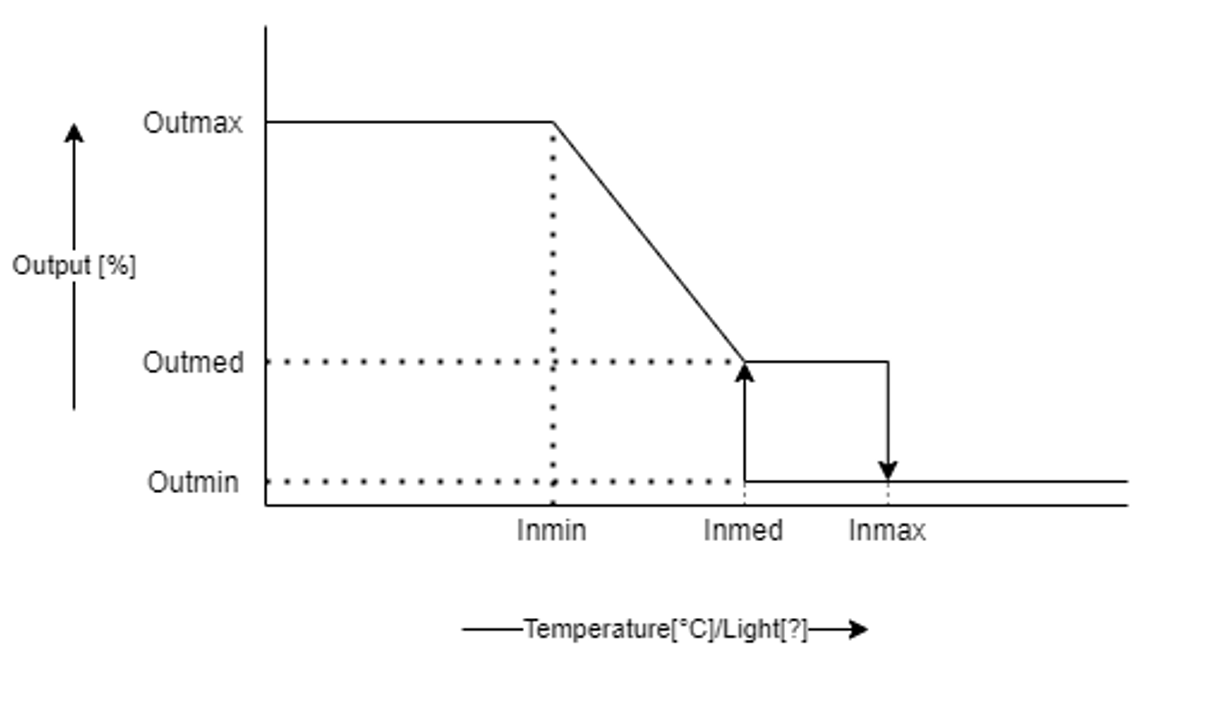

In installations exposed to extreme ambient temperatures, it is critical to monitor the temperature of the LED system in real-time. For environments where temperatures may range from -25°C to +40°C or higher, preventing the LED engine from exceeding its maximum operating temperature is essential for maintaining its longevity. The MaNima Pollux measures the temperature of both the LED engine and the housing. Based on this real-time data, the Pollux can adjust the maximum output voltage and/or current to ensure the LED engine does not exceed its safe operating temperature.

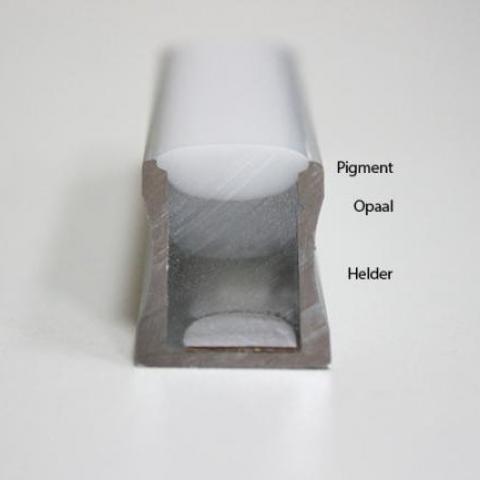

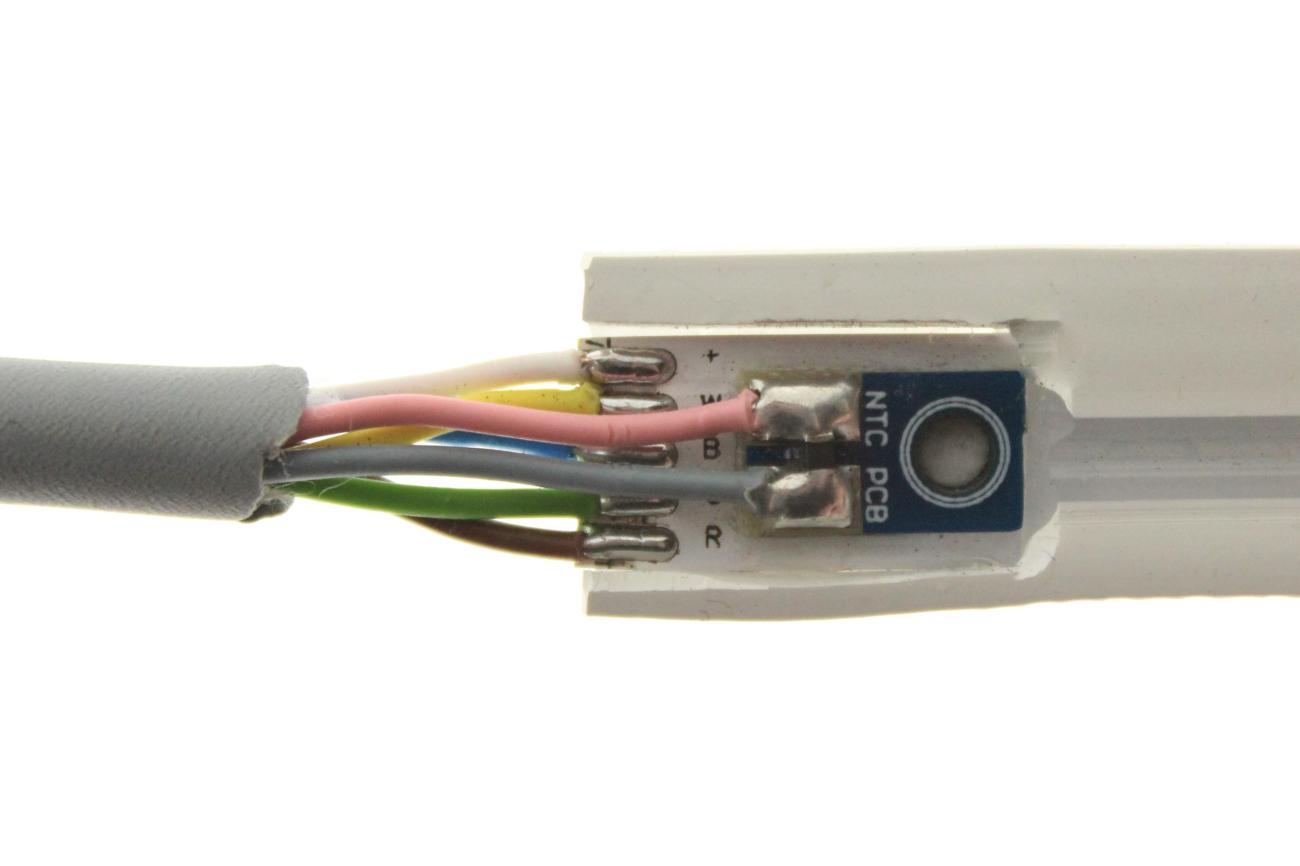

Below is an image showing an assembled profile including a built-in NTC for temperature measurements.

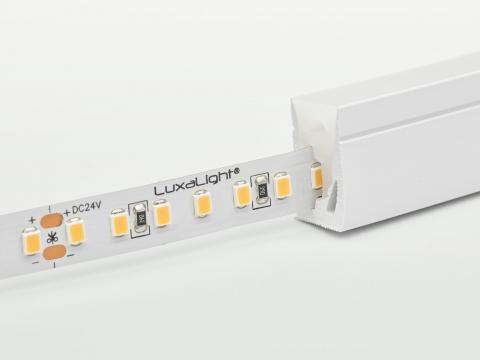

Below is an image showing a Silicon LED Extrusion with a built-in NTC sensor:

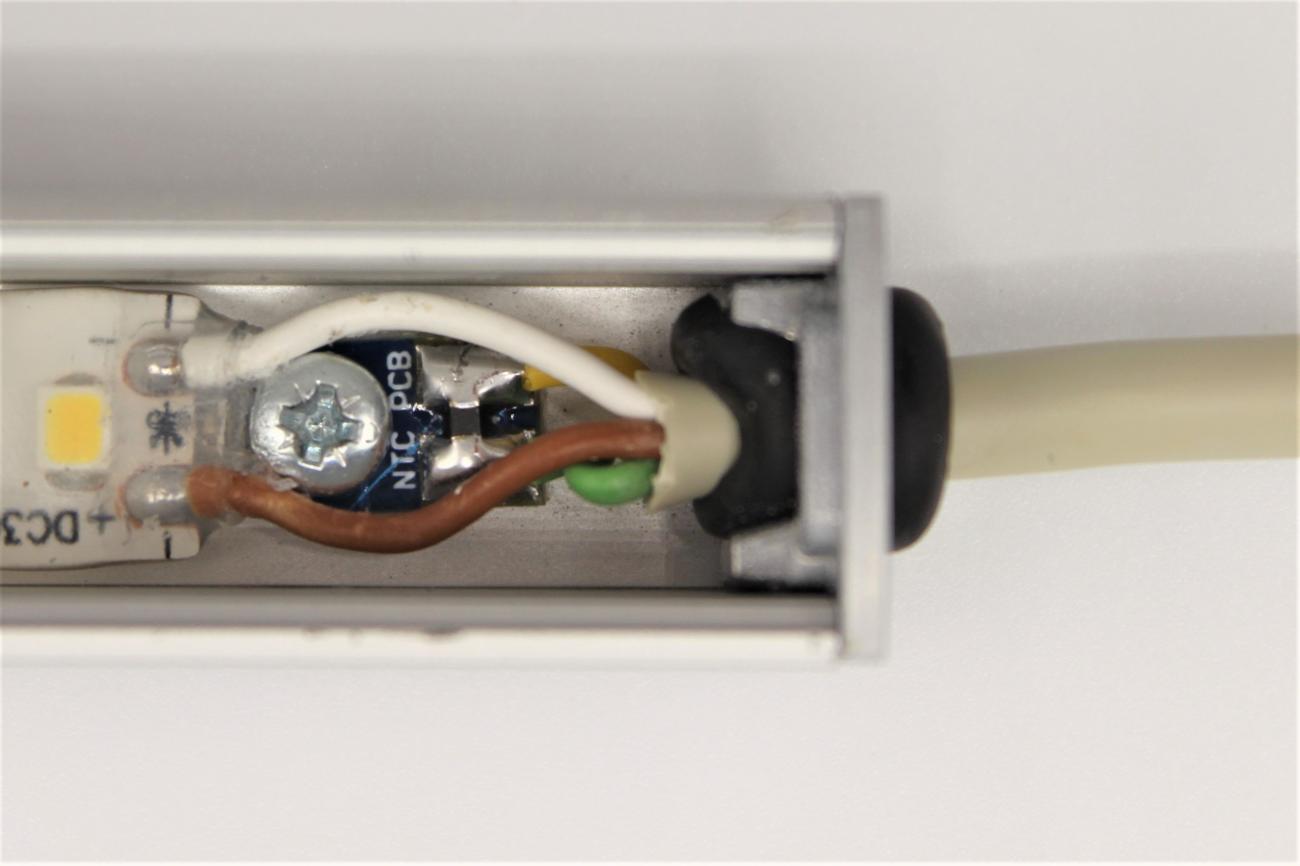

This assembled fixture features a LED Engine with an embedded NTC on the PCB:

Benefits of monitoring

- Extends the life of the LED installation

- Increases the operational reliability of the installation

- Real-time monitoring of parameters

- Real-time adaptive LED controlling

- Short circuit protection on input and output (hardware moderate)

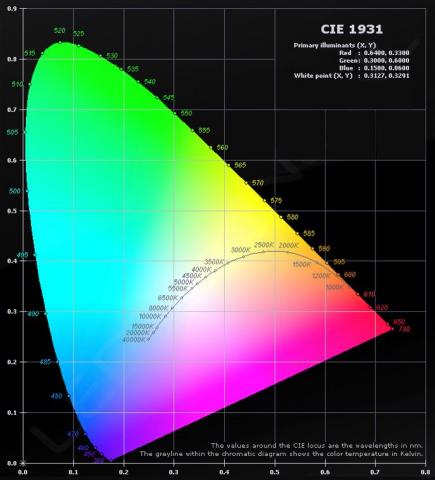

Example of a graph used for the setting life of the dimming curve in the MaNima Configurator:

Redundancy

In certain LED installations, it is crucial that the LED fixtures continue to operate at all times. This is particularly important for applications such as traffic lights, warning lights, or for difficult-to-access locations such as high-rise buildings, bridges, or underwater installations. In these cases, redundancy in the LED installation is essential. The MaNima Pollux system is equipped with both primary and secondary power inputs, allowing for a redundant power configuration. These two inputs can be used not only as individual channels but also to ensure system reliability. In the event of a failure in the primary power supply, the secondary power supply will automatically take over the function of the primary supply.

Additionally, in an LED fixture, both a primary and a secondary LED PCB (Printed Circuit Board) can be installed. If the primary LED PCB fails, the secondary LED PCB will automatically activate. The MaNima Pollux itself is fail-safe, as it includes both a software and hardware backup system.

Advantages of redundancy

- No urgent maintenance required

- Reduced and more efficient maintenance

- Backup system, both software- and hardware-based

- Increased system reliability

Delamination

LED fixtures that are equipped with casting resin must also be monitored for thermal management. The housing and casting resin have different coefficients of expansion (stretching and shrinking). At high temperatures, the difference in expansion can become too large, increasing the risk of delamination (separation of the casting resin from the housing).

System integration

MaNima interfaces can be seamlessly integrated with existing systems through custom-made APIs or standard UDP commands. Additionally, it is possible to read data from the MaNima Pollux into existing systems using UDP commands, offering flexibility in system integration.

Cloud environment

The MaNima Pollux can be connected to the MaNima Cloud. Through an M2M connection with the MaNima Cloud, LED installations can be monitored remotely, and parameters can be read in real-time. In the event of a failure or emergency, the cloud connection ensures that a message is sent to the maintenance technician. This message will include details about the nature of the fault and its location, allowing the technician to know exactly where the issue is and address it promptly. For more information on our Industry 4.0 solutions, click here. click here.