Industrial Applications of UV-A LEDs (365, 395 and 405 nm)

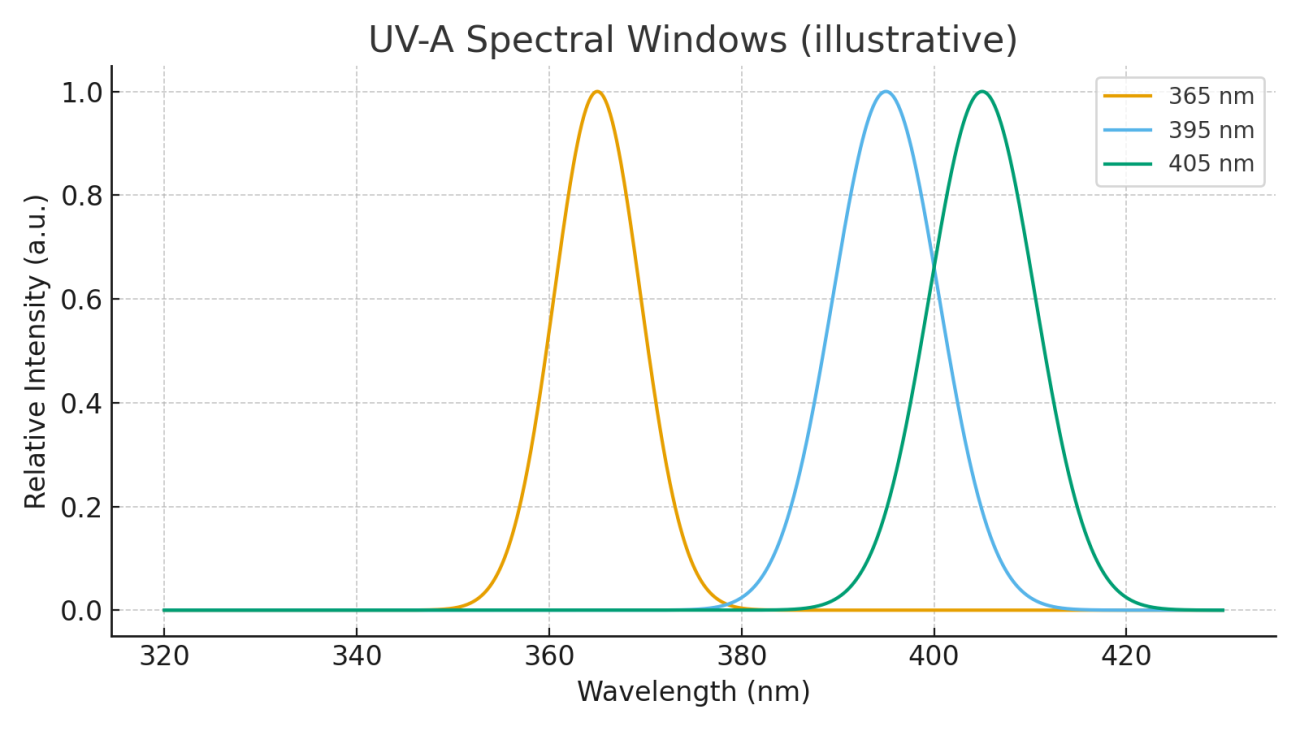

UV-A LED technology (365, 395 and 405 nm) has become a key component in modern industrial processes. With their narrow-band emission, high efficiency and precise controllability, UV-A LEDs enable engineers to design processes that are more reliable, reproducible and energy-efficient.

Applications range from curing of resins, adhesives and coatings, to machine vision & inspection, photocatalytic reactors for air and water purification, additive manufacturing, and medical uses such as photocrosslinkable hydrogels.

To meet these requirements, Zirqle, LuxaLight and MaNima Technologies together provide a modular system topology:

Zirqle LED engines – high-performance UV-A modules with integrated NTC monitoring, designed for precision, stability and scalability in industrial environments.

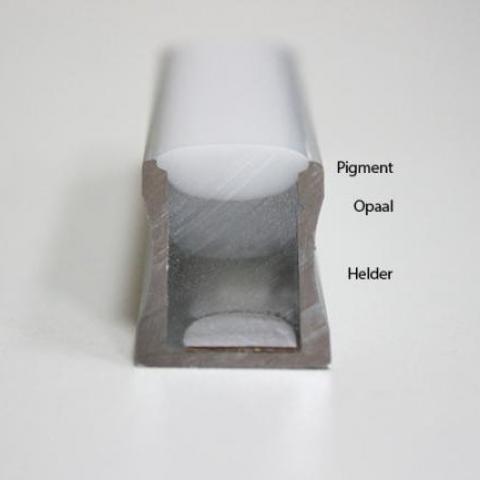

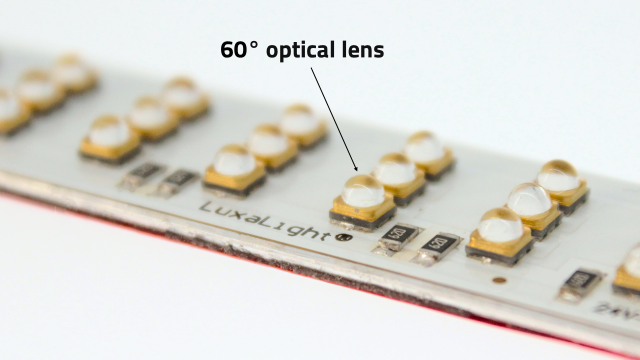

LuxaLight fixtures – scalable from compact R&D setups to large industrial panels, available in 365, 395 and 405 nm, with options for optics, housings and cooling (passive or active water/glycol).

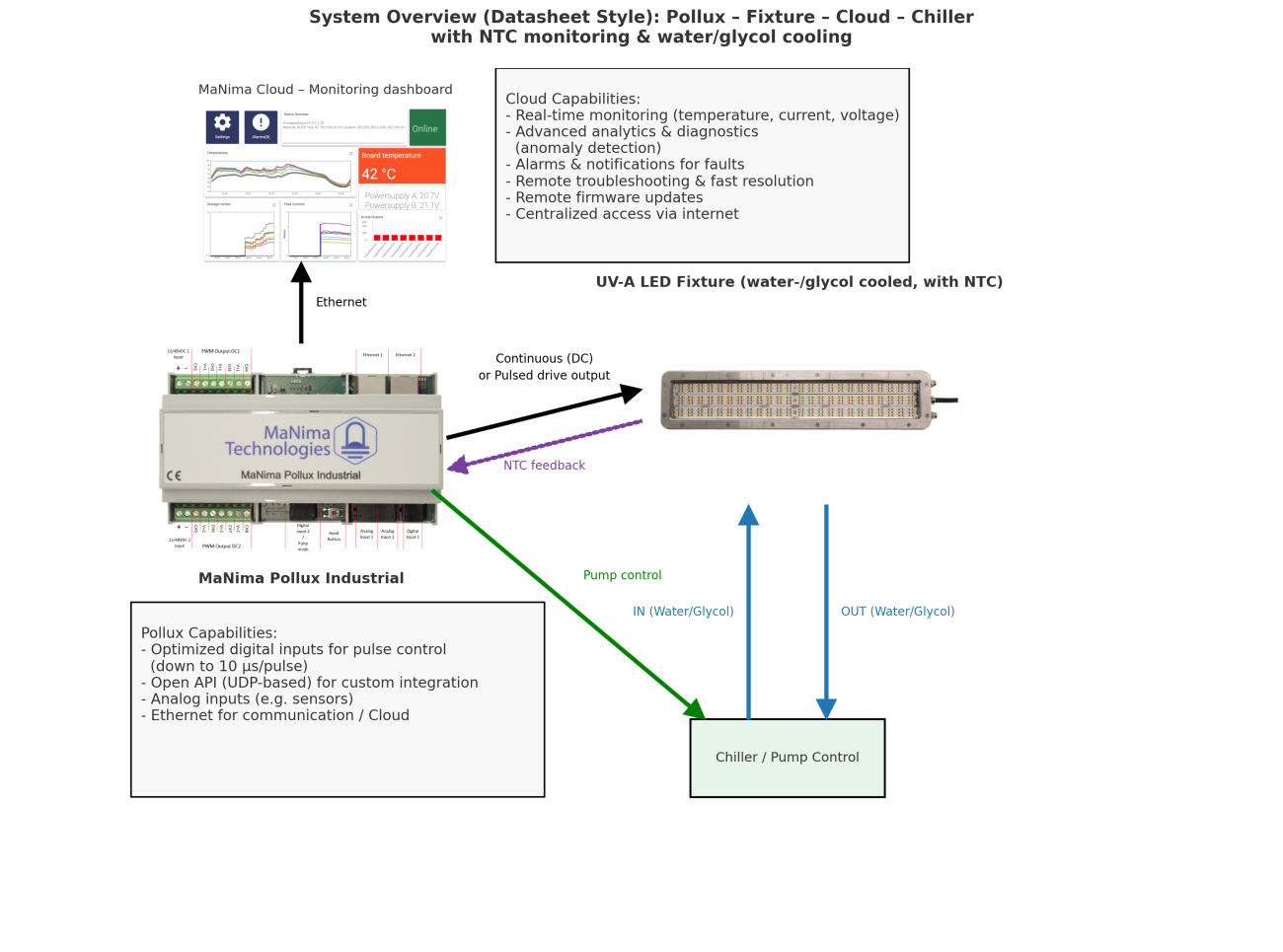

MaNima Pollux drivers – support microsecond-precision pulsing and strobing, integrated NTC feedback, and connectivity through industrial protocols.

Cloud monitoring – real-time insight into voltage, current and temperature, including alarms and data analytics.

By combining these elements, a complete system topology is created in which LED engines, fixtures, drivers and monitoring are perfectly aligned. This ensures the highest irradiance at the target surface, enabling processes to run faster, more consistently, and with improved product quality.

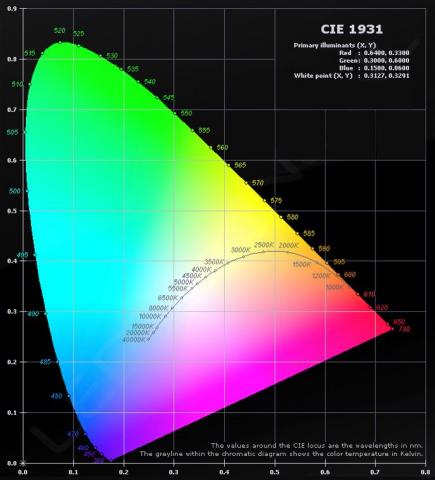

365 nm – highest photon energy | 395 nm – penetration/efficiency balance | 405 nm – near-visible, inspection & catalysis

| Wavelength | Photon Energy (relative) | Characteristics | Typical Applications |

|---|---|---|---|

| 365 nm | ★★★ (highest) | Strong absorption by photoinitiators; shallow penetration | Thin coatings, transparent adhesives, photochemistry, fluorescent detection |

| 395 nm | ★★☆ | Balance between penetration and efficiency | Inks, coatings, adhesives, inline curing, process monitoring |

| 405 nm | ★☆☆ (lowest) | Near-visible; deeper penetration into bulk materials | Photocatalysis (TiO₂), thick coatings, vision & inspection |

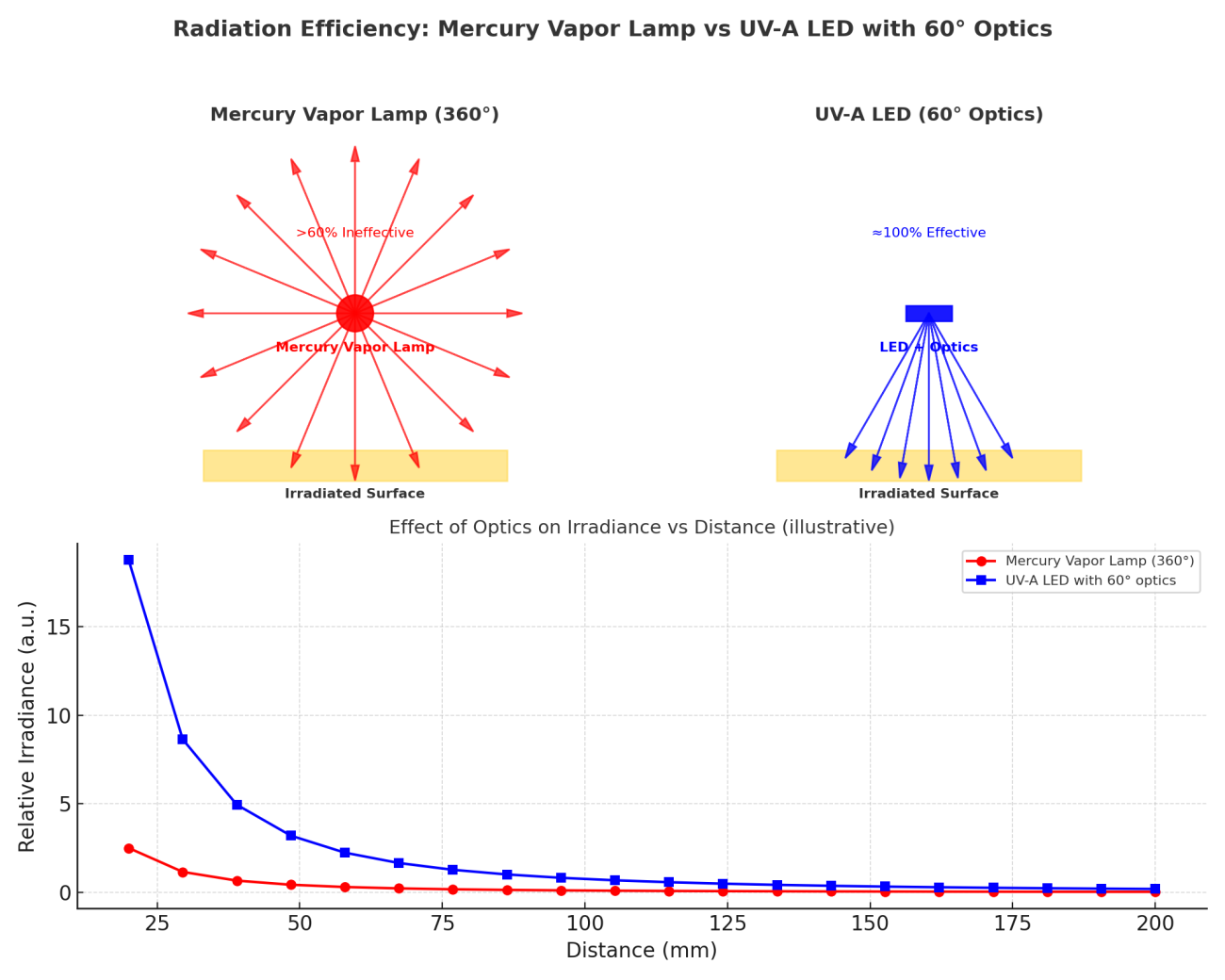

Lamp versus LED

Traditional UV-A lamps emit in all directions (360°), causing more than half of the energy to be lost. UV-A LEDs, on the other hand, feature a directed emission angle (typically 120°), ensuring that nearly all emitted photons reach the target surface effectively.

Comparison of a conventional Mercury Vapor Lamp (360°) and a UV-A LED with 60° optics.

Mercury lamps lose more than 60% of their radiation due to uncontrolled emission, while LEDs concentrate nearly all energy on the target surface. This results in up to 8× higher irradiance and faster, more consistent processes.

Focus and Optics

By combining LED modules with optics, the emission angle can be further reduced, for example to 60°. This results in a much higher irradiance (W/m²) at the target surface, without increasing the total power consumption.

This allows an engineer to choose between:

- Narrow beams with high intensity for curing, vision and precision applications.

- Wide beams without optics for homogeneous illumination of larger surfaces, such as reactors.

MaNima System Topology

Built for precision, scalability and reliability — the MaNima topology merges UV-A LED engines, fixtures, intelligent drivers and cloud monitoring into a unified, modular system.

This architecture empowers engineers to synchronize and optimize UV-A irradiation at 365, 395 and 405 nm across a variety of industrial applications — from curing and machine vision to additive manufacturing and photocatalysis. Below is the structured overview of system layers and their engineering benefits:

| Layer | Components | Key Functions | Benefits for Engineers |

|---|---|---|---|

| 1. Drive Control (Pollux) | MaNima Pollux drivers | • Continuous & pulsed current down to 10 µs resolution • Configurable pulse width, duty cycle, triggers • Interfaces: Configurator, UDP API, industrial protocols (Ethernet, digital I/O) | • Precise synchronization with PLCs, machine vision and reactors • Flexible integration into existing automation |

| 2. LED Engines & Fixtures (Zirqle & LuxaLight) | UV-A engines (365, 395, 405 nm) with NTCs Modular fixtures with passive aluminium or active water/glycol cooling Optical modules (e.g. 60° quartz lenses) | • Thermal monitoring at PCB level • Passive or active cooling depending on power level • Optics increase irradiance up to 8× | • Scalable from R&D setups to full production • Higher irradiance and stability at the target |

| 3. Monitoring & Thermal Feedback | Embedded NTC sensors Integration with chillers and pump controllers Pollux closed-loop regulation | • Real-time feedback of temperature, current and voltage • Automatic adjustment of drive current • Closed-loop thermal management via chiller/pump control | • Stable irradiance even under high duty cycles • Extended LED lifetime • Safe operation at high power |

| 4. Cloud & Analytics | MaNima Cloud dashboards & API | • Real-time logging (T, V, I, irradiance) • Predictive maintenance • Remote diagnostics & firmware updates | • Full process transparency • Reduced downtime • Future-proof integration |

LED Engines and Fixtures

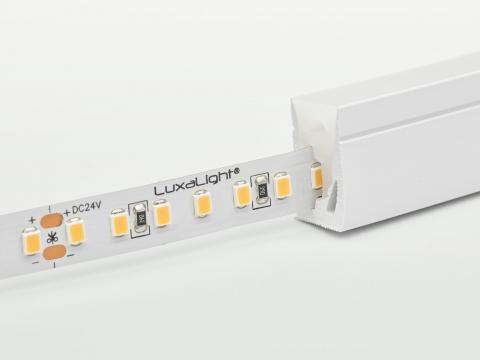

The MaNima system supports a wide range of UV-A light sources, provided by both Zirqle and LuxaLight. Engineers can choose between individual LED engines or complete fixtures depending on the application requirements.

LED Engines – Compact UV-A modules (365, 395, 405 nm) with integrated NTC sensors for precise thermal feedback. Ideal for custom integration or OEM designs.

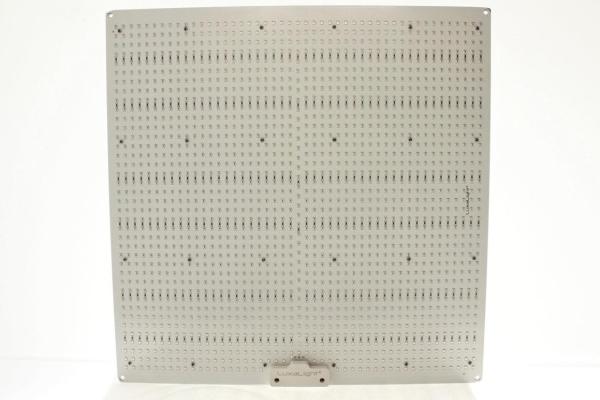

Plate Fixtures – Modular flat-panel assemblies for homogeneous irradiation over larger surfaces. Suitable for curing, coatings and inline inspection.

Water-Cooled Fixtures – High-power solutions with integrated water/glycol channels and stainless steel housings. Designed for continuous operation in demanding industrial environments.

Moulded (Encapsulated) Fixtures – Fully potted fixtures with protective encapsulation for harsh environments. Resistant to dust, moisture and chemicals, ensuring long-term stability.

This modular portfolio enables engineers to select the optimal configuration — from single engines for R&D setups to rugged, water-cooled fixtures for large-scale industrial processes.