LuxaLight Industrial LED Fixture Opaline cover UV-A 405nm 24.2x16mm (24 Volt, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 11.71 W/sqm |

| 10cm | 4.74 W/sqm |

| 15cm | 2.37 W/sqm |

| 20cm | 1.43 W/sqm |

| 25cm | 0.94 W/sqm |

| 30cm | 0.72 W/sqm |

| 24V | |

|---|---|

| 5cm | 222.53 W/sqm |

| 10cm | 93.31 W/sqm |

| 15cm | 47.3 W/sqm |

| 20cm | 29.03 W/sqm |

| 25cm | 19.1 W/sqm |

| 30cm | 14.61 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

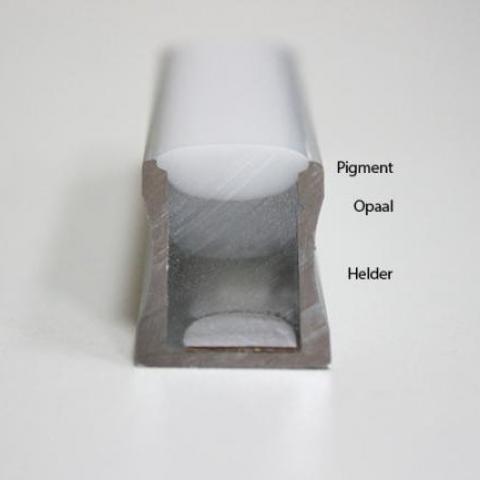

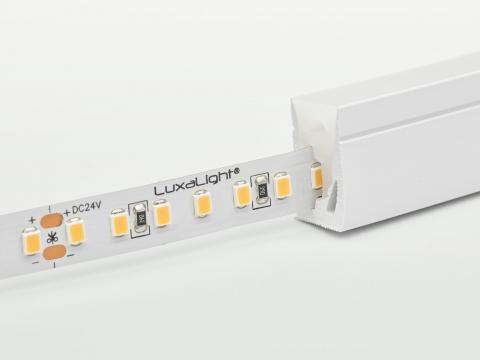

The LuxaLight Industrial LED Fixture Opaline Cover UV-A 405 nm (24.2 × 16 mm) is engineered for demanding industrial environments where durability, precision, and uniform UV illumination are essential. The opaline diffuser ensures homogeneous distribution, minimizing hotspots and enhancing process consistency. Its modular architecture (scalable from 220 mm to 3000 mm) and seamless compatibility with the MaNima Pollux Industrial System make it an ideal choice for curing, inspection, photochemistry, and disinfection.

Key Specifications

| Property | Value / Description |

|---|---|

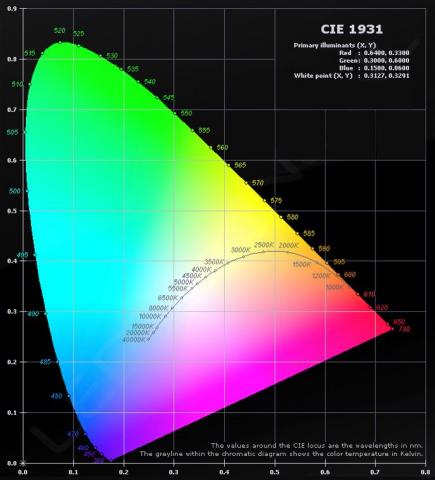

| Wavelength | 405 nm (UV-A) — peak measured ~404 nm |

| Irradiance (5 cm) | ~223 W/m² (Total irradiance) |

| Cover | Opaline PMMA for diffused, uniform emission |

| Beam angle | 120° |

| Dimensions | 220 × 24.2 × 16 mm (fixture profile) |

| Supply & Protection | 24 V DC / ~30 W, integrated NTC sensor, IP-68 |

| Electronics (ref.) | 24 V, 1.25 A, ~30 W; NTC 5 kΩ, β=3950 |

| PCB Protection | Industrial-grade silicone coating (dust, moisture, chemical resistance) |

| Thermal Monitoring | Integrated NTC sensor, controllable via MaNima Pollux Industrial System |

| Pulsing/Strobing | Supported when integrated with MaNima Pollux Industrial System |

| Environment | Designed for industrial conditions (dust, vibration, moisture) |

Applications

- UV curing of coatings, resins, and adhesives where uniform exposure is required

- Fluorescence inspection (labels, tracers, sealants) with diffuse UV excitation

- Photochemical activation in laboratory setups or reactors

- Machine vision using 405 nm-sensitive materials with reduced glare and stray light, thanks to the opaline cover

- Surface treatment, disinfection, or material-ageing tests with controlled homogeneous illumination

Also applicable in R&D and specialized lighting setups.

Benefits for Engineers

- Process stability via homogeneous illumination—minimizes hotspots and improves repeatability

- Consistent performance with thermal feedback for enhanced reliability and longer LED lifetime

- Rugged industrial design: IP-68 rating, silicone-coated PCB, opaline cover for dust and moisture protection

- Modular and scalable design: customizable length and configuration per application

- Seamless integration: plug-and-play compatibility for both production and R&D environments

Integration with MaNima Pollux Industrial System

- Real-time NTC sensor control and feedback

- Pulsing/strobing capabilities enable higher peak irradiance

- Prevents thermal overload while maximizing UV output

- Provides process data easily integrated with PLC/SCADA systems

- Open UDP-based API for straightforward system integration and customization