LuxaLight LED Engine UV-A 365nm Protected (24 Volt, 108 LEDs, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 26.57 W/sqm |

| 10cm | 11.96 W/sqm |

| 15cm | 6.18 W/sqm |

| 20cm | 3.8 W/sqm |

| 25cm | 2.49 W/sqm |

| 30cm | 1.84 W/sqm |

| 24V | |

|---|---|

| 5cm | 353.6 W/sqm |

| 10cm | 158.1 W/sqm |

| 15cm | 83.74 W/sqm |

| 20cm | 51.78 W/sqm |

| 25cm | 33.83 W/sqm |

| 30cm | 24.68 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

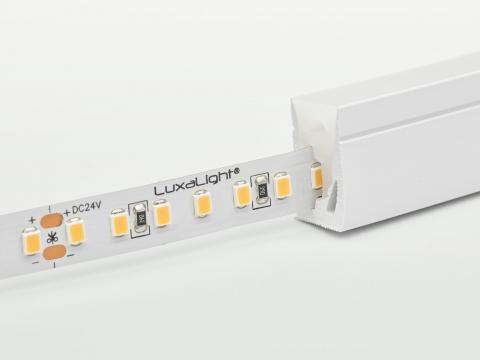

The LuxaLight LED Engine UV 365 nm (Protected, 24 V) is a semi-finished aluminum PCB module, developed for engineers and OEMs who require high-performance UV-A radiation for integration into industrial, medical, forensic, or R&D systems. Delivered as a light-emitting core, it provides maximum flexibility in housing, optics, and thermal management.

With 108 × 2835 SMD LEDs, an industrial silicone coating ensuring IP64 protection, and an integrated NTC sensor, the module delivers stable and durable performance. Combined with the MaNima Pollux Industrial System, it becomes a complete, high-efficiency UV-A solution, enabling pulsed operation, thermal monitoring, and advanced integration into automation platforms.

Key Specifications

| Property | Value / Description |

|---|---|

| Type | LED Engine – semi-finished PCB module |

| LEDs | 108 × 2835 SMD LEDs |

| PCB base | Aluminum |

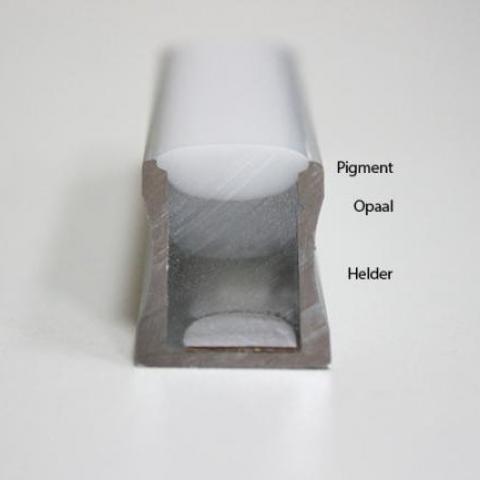

| PCB protection | Industrial silicone coating (IP64) |

| Dimensions | 200 × 20 × 2 mm (modular design) |

| Supply | 24 V DC / ~30 W |

| Wavelength | 365 nm UV-A |

| Irradiance (5 cm) | ~412 W/m² (typical UV output) |

| PPFD (5 cm) | Not applicable (outside PAR range) |

| Illuminance (5 cm) | Not applicable (UV not visible to human eye) |

| Beam angle | 120° |

| Thermal monitoring | Integrated NTC sensor (5 kΩ, β = 3950) |

Applications

- UV curing (inks, resins, adhesives, coatings) – initiates fast, low-temperature polymerization in printing, 3D printing, electronics, and industrial processes.

- Fluorescence & forensic analysis – excites fluorescent compounds in biological samples, minerals, inks, and security features for high-contrast imaging.

- Document & currency verification – reveals hidden safety markings, counterfeit detection, and anti-tampering features under UV.

- Material inspection & quality control – exposes invisible surface defects, contamination, or impurities in plastics, glass, and packaging.

- Medical diagnostics & dermatology – used in Wood’s lamp techniques to detect skin disorders, infections, or porphyrins via induced fluorescence.

- Sterilization & disinfection support – activates UV-sensitive compounds and photocatalysts for germ reduction on surfaces, air, and water.

- Environmental, food & agricultural research – enables non-destructive fluorescence analysis of water quality, crop health, and food integrity.

- R&D & sensor calibration – stable UV-A reference source for spectroscopy, device testing, and experimental setups.

Benefits for Engineers

- Semi-finished module – flexible integration for OEMs and R&D setups

- Perfect Pollux companion – becomes a complete, controllable UV-A system with MaNima Pollux

- Strong UV-A output – ~412 W/m² at 5 cm for demanding applications

- Design freedom – housing, optics, and thermal management remain customizable

- Thermal safety – integrated NTC sensor ensures stable operation and extended lifetime

- Modular scalability – multiple modules can be combined for larger coverage

- Industrial robustness – IP64 protection via silicone coating

Integration with MaNima Pollux Industrial System

- Real-time NTC temperature monitoring

- Pulse/strobe modes for enhanced UV-A efficiency

- Prevents overheating while maintaining high performance

- Compatible with PLC/SCADA for industrial automation

- Open UDP API for advanced system integration