LuxaLight Industrial LED Fixture Quartz Glass UV-A 365nm 26.6x23.5mm (24 Volt, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 26.573 W/sqm |

| 10cm | 11.9593 W/sqm |

| 15cm | 6.17532 W/sqm |

| 20cm | 3.79817 W/sqm |

| 25cm | 2.48874 W/sqm |

| 30cm | 1.84494 W/sqm |

| 24V | |

|---|---|

| 5cm | 353.6 W/sqm |

| 10cm | 158.1 W/sqm |

| 15cm | 83.74 W/sqm |

| 20cm | 51.78 W/sqm |

| 25cm | 33.83 W/sqm |

| 30cm | 24.68 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

- Multiple wavelengths in one housing

- No optics required due to high output

- Customizable cable output and / or connector

- Wide range of mounting options

- In-house expertise to personally advice on LED fixture customization

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

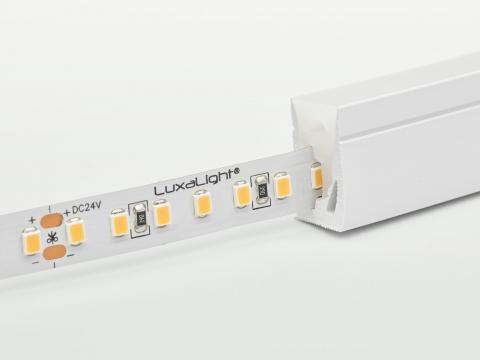

The LuxaLight Industrial LED Fixture Quartz Glass UV-A 365 nm (26.6 x 23.5 mm) is designed for demanding industrial environments where durability, precision, and high radiant intensity are essential.

Its modular design (scalable up to 220 mm up to 3000 mm), quartz glass protection, and compatibility with the MaNima Pollux Industrial System make it a robust and flexible solution for curing, photochemistry, disinfection, machine vision, and additive manufacturing.

Key Specifications

| Property | Value / Description |

|---|---|

| Wavelength | 365 nm UV-A (peak ~369 nm) |

| Optical Output | High radiant intensity, engineered for industrial use |

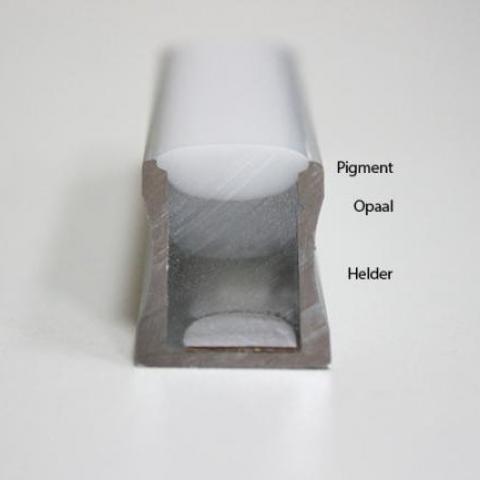

| Cover | Quartz glass for maximum UV transmission and mechanical strength |

| PCB Protection | Industrial-grade silicone coating (dust, moisture, chemical resistance) |

| Thermal Monitoring | Integrated NTC sensor, controllable via MaNima Pollux Industrial System |

| Pulsing/Strobing | Supported when integrated with MaNima Pollux Industrial |

| Design | Modular and scalable, adaptable from 220 mm up to 3000 mm |

| Dimensions | 26.6 x 23.5 mm (fixture profile) |

| Environment | Built for harsh industrial conditions (dust, vibration, moisture) |

Applications

- UV curing of coatings and inks – printing, packaging, automotive, electronics

- Adhesive & resin curing – bonding, potting, encapsulation in industrial and medical assemblies

- Photochemical processes – polymerization, reactors, laboratory chemistry

- Surface disinfection – cleanrooms, medical/lab equipment, industrial production lines

- 3D printing – additive manufacturing with UV-curable resins

- Machine vision & inspection – fluorescence excitation and quality control

Also suitable for optical bonding, semiconductor processing, and R&D environments.

Benefits for Engineers

- Process efficiency: pulsing and monitoring supported when integrated with MaNima Pollux Industrial

- Consistent performance: real-time thermal feedback prevents degradation and ensures lifetime stability

- Industrial robustness: resistant to dust, moisture, vibration, and chemical stress

- Modular scalability: fixture length and configuration tailored to the application

- Easy integration: designed for seamless use in production lines and test setups

Integration with MaNima Pollux Industrial System

- Real-time readout and control of NTC thermal sensors

- Full support for pulsing/strobing operation of the fixture

- Increased peak intensity without thermal overload

- Process data available for industrial automation (PLC/SCADA integration)

- Open API (UDP-based) for system integration and custom industrial applications