LuxaLight Industrial LED Fixture Transparent cover UV-A 395nm 24.2x16mm (24 Volt, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 29.4479 W/sqm |

| 10cm | 11.1859 W/sqm |

| 15cm | 5.70155 W/sqm |

| 20cm | 3.45532 W/sqm |

| 25cm | 2.33018 W/sqm |

| 30cm | 1.70424 W/sqm |

| 24V | |

|---|---|

| 5cm | 486.4 W/sqm |

| 10cm | 194 W/sqm |

| 15cm | 100.3 W/sqm |

| 20cm | 61.2 W/sqm |

| 25cm | 40.96 W/sqm |

| 30cm | 30.29 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

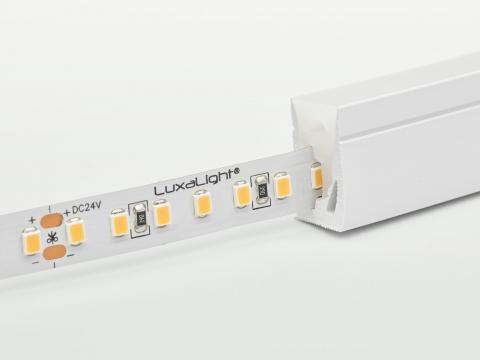

The LuxaLight Industrial LED Fixture Transparent PMMA Cover UV-A 395 nm (24.2 x 16 mm) is designed for demanding industrial environments where durability, precision, and high radiant intensity are essential.

Its modular design (scalable from 220 mm up to 3000 mm), the transparent PMMA cover – optimized for 395 nm UV transmission – and compatibility with the MaNima Pollux Industrial System make it a robust and flexible solution for curing, photochemistry, disinfection, machine vision, and additive manufacturing.

Specifications

| Property | Value / Description |

|---|---|

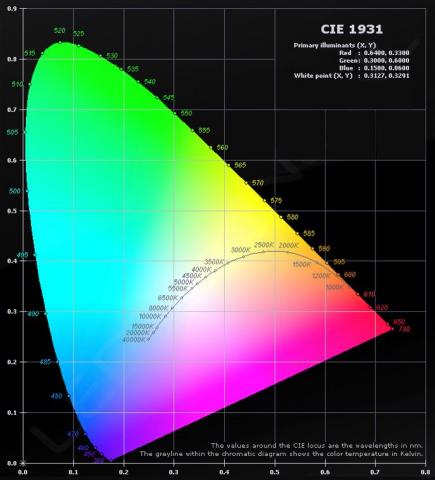

| Wavelength | 395 nm UV-A (peak ~397 nm) |

| Optical Output | High radiant intensity, engineered for industrial use |

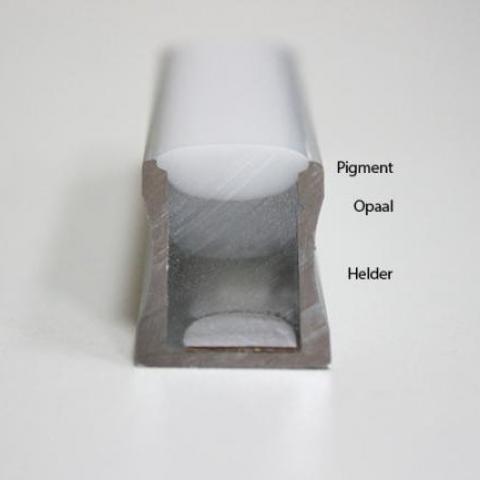

| Cover | Transparent PMMA cover – optimized for 395 nm, maintains high UV transmission |

| PCB Protection | Industrial-grade silicone coating (dust, moisture, chemical resistance) |

| Thermal Monitoring | Integrated NTC sensor, controllable via MaNima Pollux Industrial System |

| Pulsing/Strobing | Supported when integrated with MaNima Pollux Industrial |

| Design | Modular and scalable, adaptable from 220 mm up to 3000 mm |

| Dimensions | 24.2 x 16 mm (fixture profile) |

| Environment | Built for harsh industrial conditions (dust, vibration, moisture) |

Applications

- Cost-effective UV curing of coatings and inks – printing, packaging, electronics

- Adhesive & resin curing – suitable for photoinitiators responsive at 385–405 nm

- Machine vision & inspection – fluorescence excitation for quality control, material detection, and security marking

- Blacklight and visual inspection – detection of optical brighteners, inks, adhesives, and contaminants

- 3D printing – compatible with resins designed for 385–405 nm range

- Surface disinfection (limited) – effective mainly in controlled environments with extended exposure

Also applicable in optical bonding and R&D environments.

Benefits for Engineers

- Process efficiency: pulsing and monitoring supported when integrated with MaNima Pollux Industrial

- Consistent performance: real-time thermal feedback prevents degradation and ensures lifetime stability

- Industrial robustness: resistant to dust, moisture, vibration, and chemical stress

- Modular scalability: fixture length and configuration tailored to the application

- Easy integration: designed for seamless use in production lines and test setups

Integration with MaNima Pollux Industrial System

- Real-time readout and control of NTC thermal sensors

- Full support for pulsing/strobing operation of the fixture

- Increased peak intensity without thermal overload

- Process data available for industrial automation (PLC/SCADA integration)

- Open API (UDP-based) for system integration and custom industrial applications