LuxaLight Industrial LED Fixture Transparent cover Near Infrared 960nm 24.2x16mm (24 Volt, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 6.30352 W/sqm |

| 10cm | 2.34626 W/sqm |

| 15cm | 1.2149 W/sqm |

| 20cm | 0.747176 W/sqm |

| 25cm | 0.499372 W/sqm |

| 30cm | 0.374971 W/sqm |

| 24V | |

|---|---|

| 5cm | 314 W/sqm |

| 10cm | 117.3 W/sqm |

| 15cm | 60.46 W/sqm |

| 20cm | 37.4 W/sqm |

| 25cm | 25.03 W/sqm |

| 30cm | 18.88 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

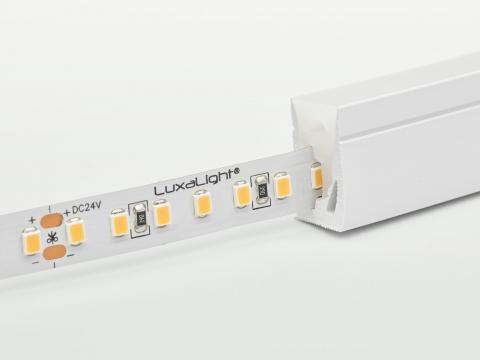

The LuxaLight Industrial LED Fixture Transparent Cover Near-Infrared 960 nm (24.2 × 16 mm) is designed for industrial environments where robust, precise and high-intensity NIR illumination is required. Its modular design (220 mm to 3000 mm), transparent PMMA cover optimized for 960 nm transmission, and compatibility with the MaNima Pollux Industrial System make it a versatile solution for curing, drying, inspection and process monitoring.

Specifications

| Property | Value / Description |

|---|---|

| Wavelength | 960 nm near-infrared (measured peak ~958 nm) |

| Optical Output | High radiant intensity tailored for NIR industrial processes |

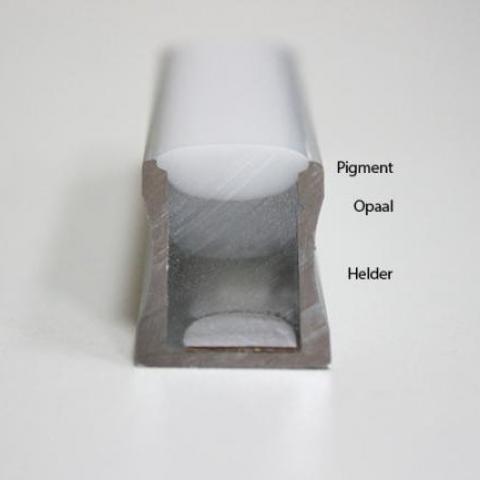

| Cover | Transparent PMMA cover optimized for efficient 960 nm transmission |

| PCB Protection | Industrial-grade silicone coating (dust, moisture, chemical resistance) |

| Environmental Protection | IP64 – dust-tight and splash-water resistant |

| Thermal Monitoring | Integrated NTC sensor, controllable via MaNima Pollux Industrial System |

| Pulsing/Strobing | Supported when integrated with MaNima Pollux Industrial System |

| Design | Modular and scalable, from 220 mm to 3000 mm |

| Dimensions | 24.2 × 16 mm (fixture profile) |

| Environment | Suitable for heavy-duty industrial conditions (dust, vibration, moisture) |

Applications

Material curing & drying – adhesives, coatings, composites using deep NIR

Photochemical processes – enhancing specific chemical reaction rates

Quality control & inspection – subsurface defect detection, coating validation

Food processing – drying and process monitoring in industrial food lines

Machine vision – NIR imaging for sorting and inspection in automation

Process monitoring – NIR illumination for inline sensing and feedback

Also applicable for advanced R&D photonic applications.

Benefits for Engineers

Efficiency: Pulsing + real-time monitoring improves throughput safely

Reliability: Thermal feedback stabilizes output and protects lifetime

Durability: Robust PMMA + IP64 rating for harsh industrial environments

Scalability: Modular design adapts up to 3000 mm lengths

Integration ready: Plug-and-play with Pollux and industrial automation

Integration with MaNima Pollux Industrial System

Real-time thermal monitoring via NTC sensor

Pulsing/strobing for higher peak output

Prevents overheating during extended use

Compatible with PLC/SCADA automation

Open API (UDP-based) for custom integration