LuxaLight LED Back Light 5700K Protected (24 Volt, 140 LEDs, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 158800 lx |

| 10cm | 82520 lx |

| 15cm | 46100 lx |

| 20cm | 29190 lx |

| 25cm | 20260 lx |

| 30cm | 15310 lx |

| 24V | |

|---|---|

| 5cm | 2501.08 umol/m2 |

| 10cm | 1304.29 umol/m2 |

| 15cm | 729.932 umol/m2 |

| 20cm | 462.758 umol/m2 |

| 25cm | 321.147 umol/m2 |

| 30cm | 242.431 umol/m2 |

| 24V | |

|---|---|

| 5cm | 4.5549 W/sqm |

| 10cm | 2.43983 W/sqm |

| 15cm | 1.36611 W/sqm |

| 20cm | 0.876133 W/sqm |

| 25cm | 0.610836 W/sqm |

| 30cm | 0.461369 W/sqm |

| 24V | |

|---|---|

| 5cm | 569.6 W/sqm |

| 10cm | 298.1 W/sqm |

| 15cm | 166.7 W/sqm |

| 20cm | 105.4 W/sqm |

| 25cm | 73.06 W/sqm |

| 30cm | 55.02 W/sqm |

- By combining Pulse Mode with Real-Time Monitoring, the efficiency of LED systems can be increased, resulting in higher output.

- We have the expertise and equipment to perform measurements tailored to the specific requirements of the application.

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

| NTC | NTC sensor |

| NTC_GND | NTC ground |

Beta value: 3950

Product description

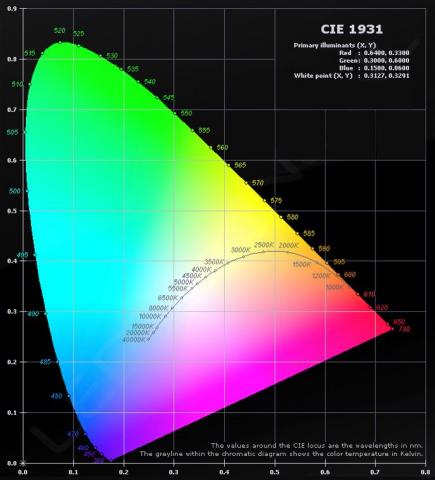

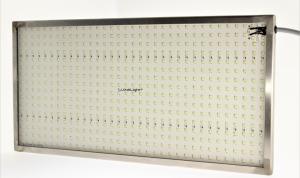

The LuxaLight Backlight PCB is designed specifically for the machine vision and robotics industries, providing a highly modular and customizable lighting solution that ensures precise and efficient illumination. With an impressive 481K Lux (KLx) output, this backlight PCB delivers exceptional brightness and uniformity, essential for accurate imaging and object detection in demanding industrial environments. The PCB is equipped with strategically placed cutouts that allow for the correct positioning of the camera lens, ensuring improved alignment and focus.

Key Features:

- 481K Lux Output (KLx): Provides exceptional brightness and high contrast, essential for machine vision applications, resulting in detailed and accurate imaging.

- Modular Design: The flexible, modular design allows for easy customization for different machine vision setups and robotics applications.

- Camera Lens Alignment Cutouts: Strategically placed cutouts ensure accurate camera lens positioning, enhancing image clarity and sharpness.

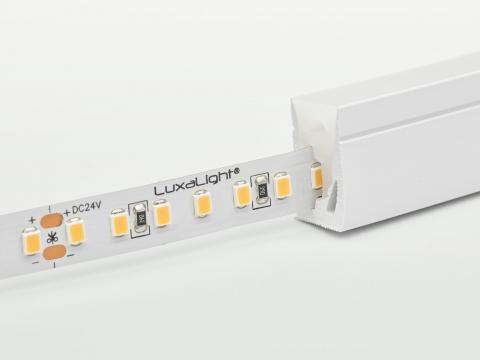

- 24V Power Supply: Operates on a reliable 24V system, ensuring efficient operation with low energy consumption, making it suitable for continuous use in industrial environments.

- Real-Time Temperature Monitoring with NTC Sensor: The integrated NTC sensor monitors temperature in real-time, preventing overheating and ensuring the optimal performance of the system.

- Pulsing Capability with MaNima Pollux Industry: The backlight PCB is compatible with the MaNima Pollux Industry system, enabling pulsing (strobing) for enhanced clarity and brightness, especially in high-speed applications.

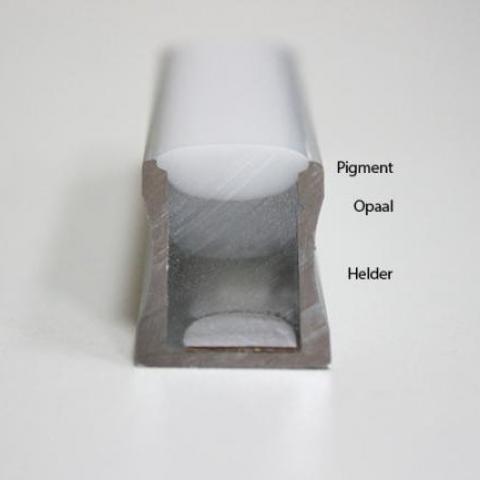

- IP64 Silicone Nano Coating: The IP64-rated silicone nano coating offers extra protection against moisture, dust, and other environmental factors, making it suitable for use in harsh industrial environments.

- Durability and Industrial Suitability: Built for industrial applications, the backlight PCB offers long-lasting reliability, even in demanding environments.

Applications:

- Machine Vision Systems: Ideal for providing precise, uniform lighting for machine vision cameras, with applications such as inspection, quality control, and automated testing.

- Robotics: Perfect for use in robotics applications where accurate object detection, sorting, or navigation is required. The ability to pulse and precise lens alignment optimizes speed and performance.

- Automated Manufacturing: Suitable for use in automated production lines for quality control, assembly, and sorting, where clear imaging is critical for quality outcomes.

- 3D Scanning and Inspection: Ideal for 3D scanning and inspection processes, where lighting is essential for capturing detailed images of complex objects and surfaces.

- Industrial Automation: Ideal for various industrial automation applications that require lighting for cameras and sensors in environments such as material handling, packaging, and assembly lines.

Benefits:

- Enhanced Imaging Accuracy: The 481K Lux output, combined with precise camera lens positioning, ensures brighter and sharper images, improving the accuracy of machine vision applications.

- Customization and Flexibility: The modular design allows for maximum adaptability to specific machine vision and robotics applications, ensuring optimal lighting.

- Real-Time Temperature Management: The NTC sensor ensures continuous temperature monitoring, maintaining ideal operating conditions and extending the lifespan of the PCB.

- Increased Efficiency with Pulsing: The MaNima Pollux Industry Pulsing feature allows for faster and clearer imaging, ideal for high-speed applications or environments with rapid movement.

- Reliability and Durability: The IP64 silicone nano coating provides extra protection against dust, moisture, and other environmental factors, ensuring the system performs optimally in industrial environments.