LuxaLight UV LED-strip 365nm Protected (24 Volt, 240 LEDs, 2835, IP64)

Technical specifications

| 24V | |

|---|---|

| 5cm | 3.85 W/sqm |

| 10cm | 1.52 W/sqm |

| 15cm | 0.76 W/sqm |

| 20cm | 0.47 W/sqm |

| 25cm | 0.31 W/sqm |

| 30cm | 0.22 W/sqm |

| 24V | |

|---|---|

| 5cm | 67.26 W/sqm |

| 10cm | 26.03 W/sqm |

| 15cm | 13.08 W/sqm |

| 20cm | 8.06 W/sqm |

| 25cm | 5.26 W/sqm |

| 30cm | 3.86 W/sqm |

| Symbol | Function |

|---|---|

| V+ | V+ |

| GND | Ground |

Product description

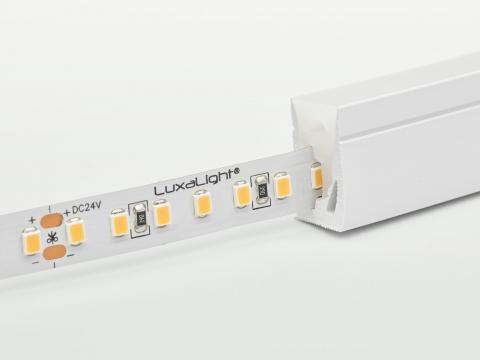

The LuxaLight UV-A LED Strip 365 nm provides powerful UV-A radiation for industrial processes requiring high UV intensity. With 240 high-quality 2835 LEDs per meter and a flexible IP64 silicone coating, this strip is designed for continuous use in demanding environments. Its flexible design (5 m reels, cuttable every 25 mm) allows easy integration into reactors, process installations, and test setups.

Fully compatible with the MaNima Pollux Industrial System for advanced control, real-time monitoring, and automatic protection.

Key Specifications

| Property | Value / Description |

|---|---|

| Wavelength | UV-A 365 nm (peak ~365 nm) |

| Irradiance (5 cm) | Total: ~67.3 W/m²; Peak: ~3.85 W/m² |

| Beam Angle | 120° |

| LED Specifications | 240 LEDs/m, type 2835 SMD |

| Dimensions | 5 m per reel; cuttable every 25 mm; width: 12 mm; height: 4 mm |

| Power & Consumption | 24 V DC; ±1 A/m; ±24 W/m |

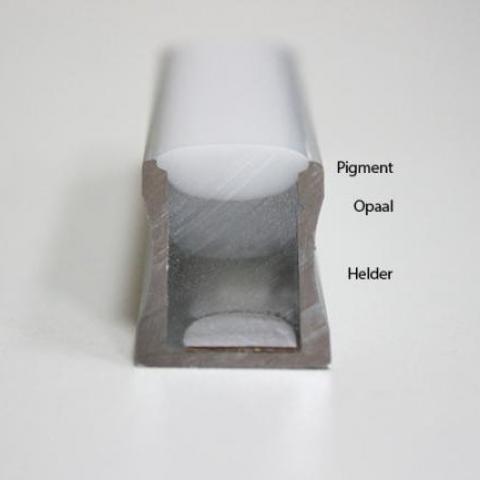

| Protection | IP64 – silicone coating, dust- and splash-water resistant |

| Thermal Monitoring | Optional via external NTC sensor (Pollux-compatible) |

| Operating Temp. | −20 °C … +60 °C (storage −40 °C … +80 °C) |

| Standards | RoHS, CE, EN60598-1, EN62031, IEC62471 |

Applications

- UV reactors for water purification and chemical processes

- Curing and photopolymerization of coatings, adhesives, inks, and resins

- Industrial surface treatment and material processing

- Pharmaceutical and medical processes requiring UV activation

- Laboratories and R&D setups for controlled UV experiments

Also applicable in R&D and specialized lighting setups.

Benefits for Engineers

- High UV output with uniform 120° beam distribution

- Flexible segment design (cuttable every 25 mm, supplied on 5 m reels)

- Robust IP64 construction for industrial environments

- Thermally stable, expandable with optional NTC sensor and Pollux monitoring

- Modular and scalable for reactors and process lines

- Easy integration with standard 24 V systems

Integration with MaNima Pollux Industrial System

- Real-time thermal monitoring via optional NTC sensor

- Pulse and strobe modes for flexible UV output

- Automatic thermal protection for reliable continuous operation

- Seamless PLC/SCADA integration for process automation

- Open UDP API for advanced system control and logging