Wavelengths especially for plant growth

A lot of research is being done for greenhouse and horticulture into stimulating plant growth by LED light. Due to a lack of sunlight, some plants cannot grow, flower properly or the effects on fruit formation are detrimental. Additional lighting is therefore necessary in this case.

Stimulation of plant development

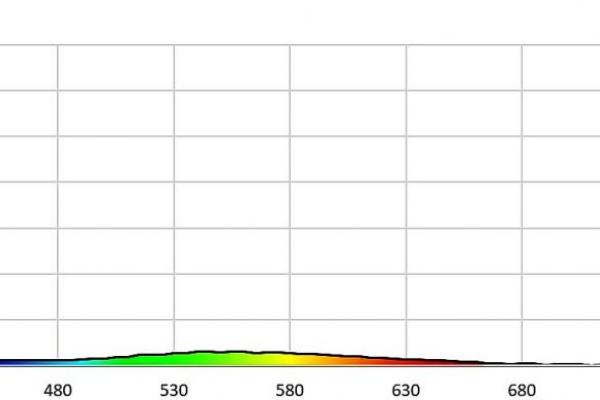

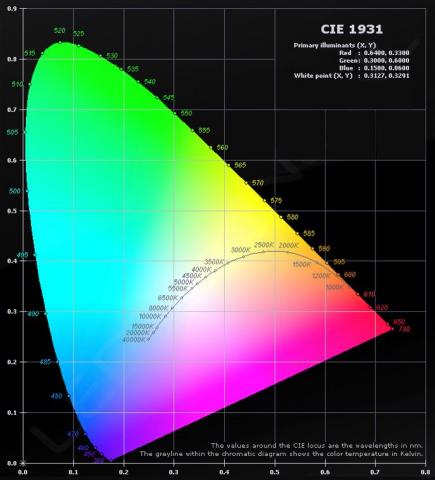

Assimilation light is light that is used to supplement natural sunlight with artificial light during the growth or flowering phase of a plant. In addition to the colors red and blue, assimilation light must also have orange, white and UV light, infrared light and deep red light for the cultivation of crops. All these types of LED light have a different wavelength in the spectrum. The phases in the development of the plant are stimulated by specific wavelengths.

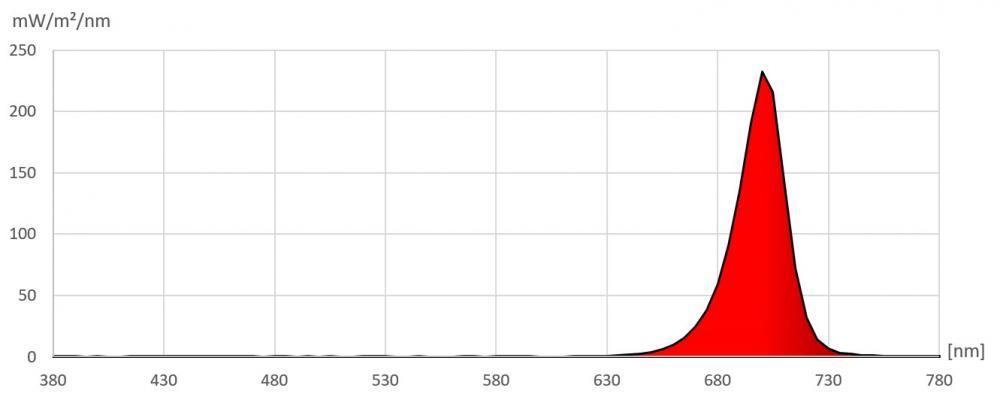

Deep red and infrared LED light

LuxaLight has developed LED strips especially for hydroponics. Think of UV- LED light, deep red LED and infrared LED light. Deep red and infrared have wavelengths of 700 nm and 800 nm respectively and are in the far red/ red edge spectrum. Flower boosters used in floriculture are a good example of this. UV-LED light for plant growth has a wavelength between 280 and 420 nanometers.

Advantages of LED

Compared to regular HPS lighting, LED offers a number of important advantages:

- LED lighting is many times safer than, for example, HPS lighting.

- Up to 60% energy savings, longer life and lower maintenance costs

- A healthier growth and flowering of plants, flowers, vegetables and fruit

- By providing the crop with the correct light spectrum, it can be harvested earlier

- With a lower wattage, a higher crop yield can be obtained.

- Less heat development, better controllable temperature in the grow room or greenhouse

Custom made LED horticultural lighting

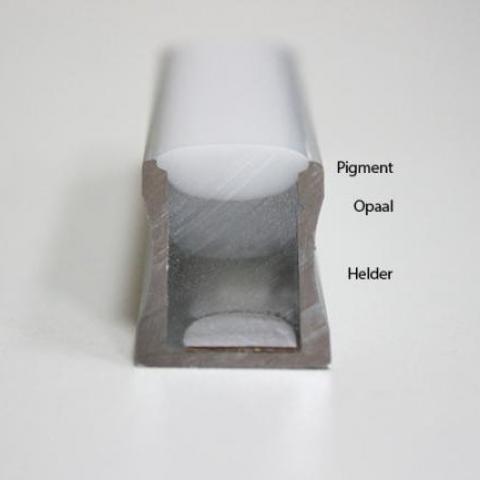

LED light for optimization of growth systems, can have the function of additional lighting, both above and between the crop, but also as a control light. The crop can be adjusted at specific times if necessary by means of control lighting. Custom-made LED fixtures are required for every lighting system in LED horticulture. Luminaires can be assembled in such a way that they have a high IK classification and IP value so that the supporting structure can be placed in damp areas or under water without any problems (LED moulding). LED luminaires can also be made for applications in a multi-layer system. The composition of the LED luminaires therefore depends on the requirements, the wavelengths used and the type of function that the LED light has. Not only luminaires can be made to measure, but also interfaces for, for example, controlling the LED luminaires, monitoring the entire LED system and for simulating a day/ night rhythm.

Components used:

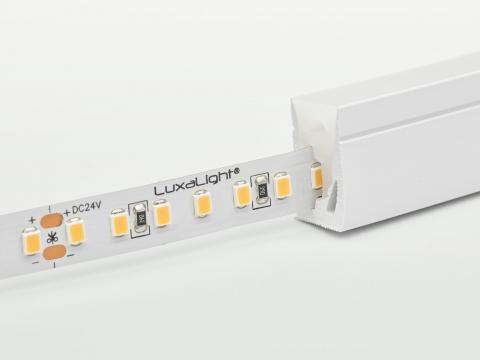

- LuxaLight Long Life Deep Red LED-strip 700nm Protected (24 Volt, 140 LEDs, 2835, IP64)

- LuxaLight Long Life Infrared LED-strip 800nm Protected (24 Volt, 140 LEDs, 2835, IP64)

- LuxaLight Long Life UV LED-strip 395nm Protected (24 Volt, 240 LEDs, 2835, IP64)