LED architectural lighting in concrete element

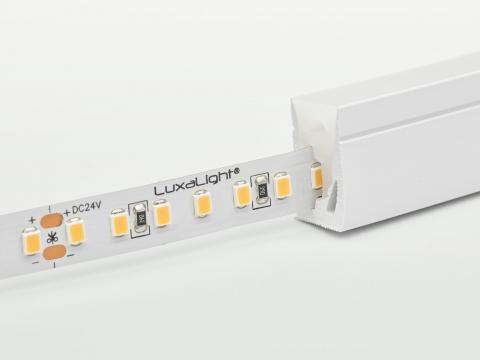

This LED architectural lighting is a durable eye-catcher. The LED lines are located in a concrete element of a floor and are therefore subject to various weather conditions. For this reason, the LED lines must be UV stable and have a high IP value.

Shrinkage and expansion

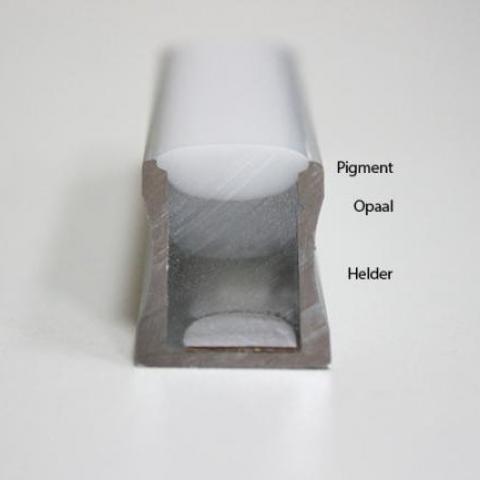

Another important factor to take into account is the heat development of the LED lighting. These LED lines are in fact incorporated into concrete elements, which can reach temperatures of more than 50 degrees Celsius in the summer months. The profiles will expand due to the high temperatures. The composition of the casting resin must be adapted to the expansion and contraction, so that any heat stress is absorbed.

Voltage drop

The entire installation is controlled by a few LED drivers. However, placing these LED drivers was only possible at a distance of 150 meters from the LED lines. As a result, the installation has more than 150 meters of cable, which can result in a voltage drop. To counter this, the LuxaLight voltage driver for voltage drop compensation was used as LED driver.

Mechanical drawing

The entire installation is drawn out mechanically. Proper drawing is extremely important in this project because of the anchoring in the concrete and the real temperature differences of more than 50 degrees. If this is not done according to the set requirements, it may mean that the installation will be damaged due to the stretch and shrinkage.

Prefab delivery

Everything is assembled and delivered prefab so that the installation of the LED lines is faster and more efficient. The manufacturing process takes place in a specialized and controlled environment, so we can also guarantee a higher and constant quality. When assembly and LED molding takes place on location, external factors such as the weather conditions that can influence the casting of the LED application must also be taken into account.

Components used: