Special moulding technique for large LED tiles

Is it possible to develop an LED tile that can be used both as a floor tile in a swimming pool and as a terrace tile?

LED tile

A waterproof LED tile has been manufactured, measuring 1 by 1 meter with a maximum height of a few centimeters due to the shallow installation depth. The waterproof LED floor tile is placed in a height-adjustable floor.

LED as functional and accent lighting

The LED tile functions as both functional LED lighting and accent LED lighting. The function of the LED tile is determined by adjusting the height of the bottom. When the LED floor part is in use as a terrace, the lighting aims to illuminate accents. In the swimming pool, the LED tile serves as functional lighting. So there is no longer any need for “separate” LED pool lighting.

LED matrix

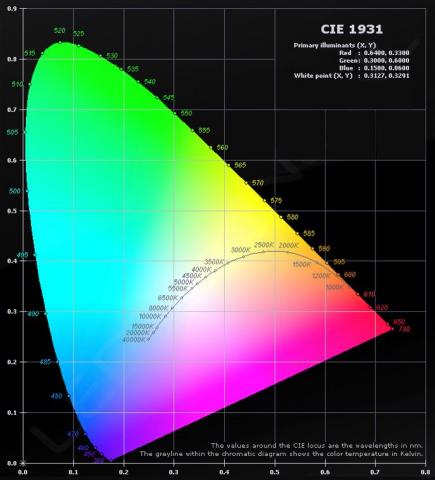

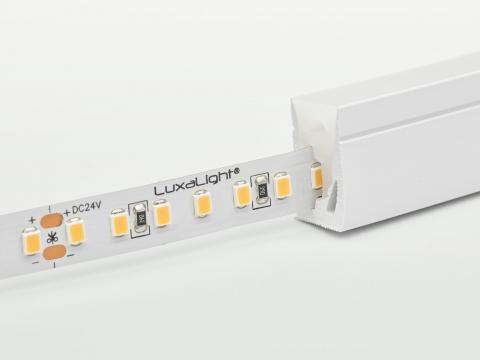

A LED matrix has been used to make the tile completely diffuse. A LED matrix has a high LED density, which means that there are no visible hotspots. Another advantage is that the LED Matrix has RGB LEDs so that the LED lighting can change light color.

IK classification

The requirements for LED in underwater applications and outdoor use are high. For example, the LED application must of course not only be completely waterproof, have a high IK value, but the heat management must also be well regulated. Because the LED tile is placed as a floor tile in the swimming pool or can be used as a terrace, this means that this tile must have a certain impact resistance (IK value). To guarantee the impact resistance and watertightness, the only option is LED moulding/ LED casting.

Moulding LED tile

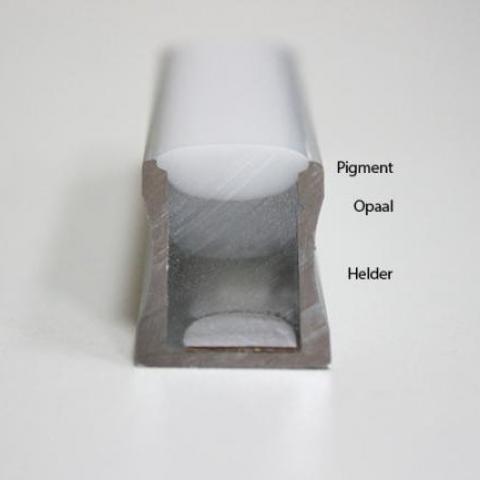

The LED tile is cast with a special casting resin. When large surfaces are poured in, one has to deal with stretching and shrinking of the casting resin. During the chemical process that takes place during curing, it will shrink. The larger the cast-in surface, the greater the shrinkage. The composition of the casting resin is adjusted in the correct proportion based on the application and shrinkage. The light image of the LED tile must be diffuse for both applications. To get the light image completely evenly diffuse, the tile is provided with 3 different layers of casting resin.

Heat regulation

The lifespan and light output of the cast-in LED tile can be greatly reduced if the heat regulation is not good. This should be taken into account when casting LED applications. To create the correct heat conduction, high efficiency LEDs have been used, they have a lower heat development than a normal low efficiency LED.